MMC QTV Vision Systems

Unmatched Precision, Flexibility and Innovative Features at High Speed

MMC vision systems leverage advanced custom algorithms and machine learning to ensure the safety and security of your projects, while minimizing false rejects. With a seamless integration to controls though a single HMI, ease of integration into your production line, and both on-board and off-board options, we deliver advanced cavity recognition, detection of cap anomalies, contaminants, geometrical defects, liner integrity, color, contour deviation and virtually any type of damage, at up to 2400ppm.

Send us your closures and schedule a demo with our vision team.

MMC VISION SYSTEMS

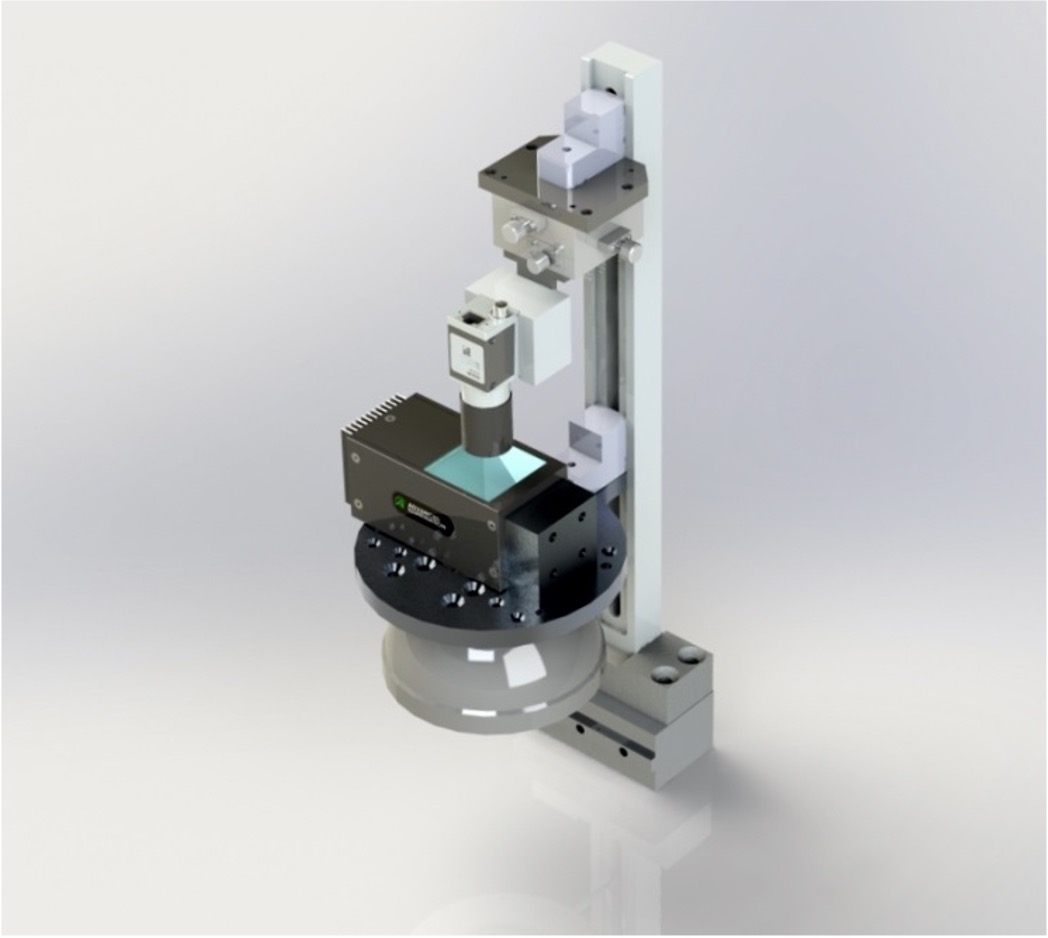

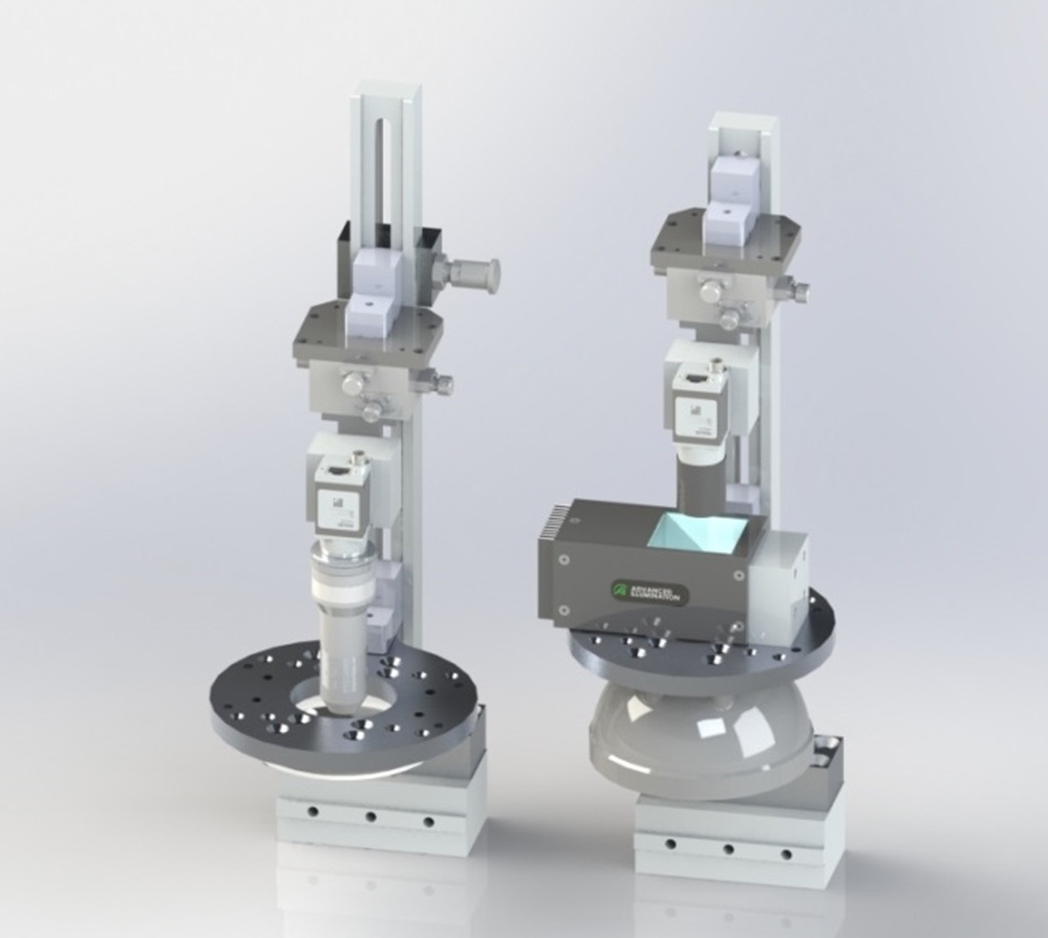

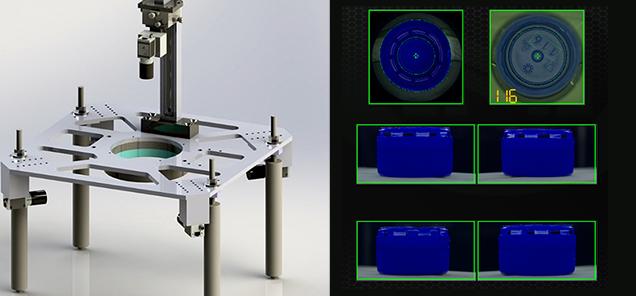

Our QTV systems are custom tailored to your specific project and closure. With both on-board and off-board options, including custom inspections tailored to closure applications requiring radial orientation, our systems can be integrated into existing or new automation systems.

ALL ROUND 360° INSPECTION

Our Most complete inspection solution tailored to projects where 360 degree closure inspection is critical to project success.

TELL US ABOUT YOUR PROJECT

CUSTOM INSPECTION

Our Vision team has a wide range of experience designing custom inspection systems for sports closures, closures with complex geometry, multi-part closures requiring complex assembly and radial orientation.

TELL US ABOUT YOUR PROJECT

CAVITY RECOGNITION

Our advanced and proprietary algorithms enable our systems to accurately perform optical character recognition with high precision and speed. This provides our clients with the capability to sample and link rejects to specific cavity numbers.

TELL US ABOUT YOUR PROJECT

Schedule a demo with our Vision Team and tell us about your project or challenge. We'd love to hear from you.

or get an in person demo at the NPE 2024

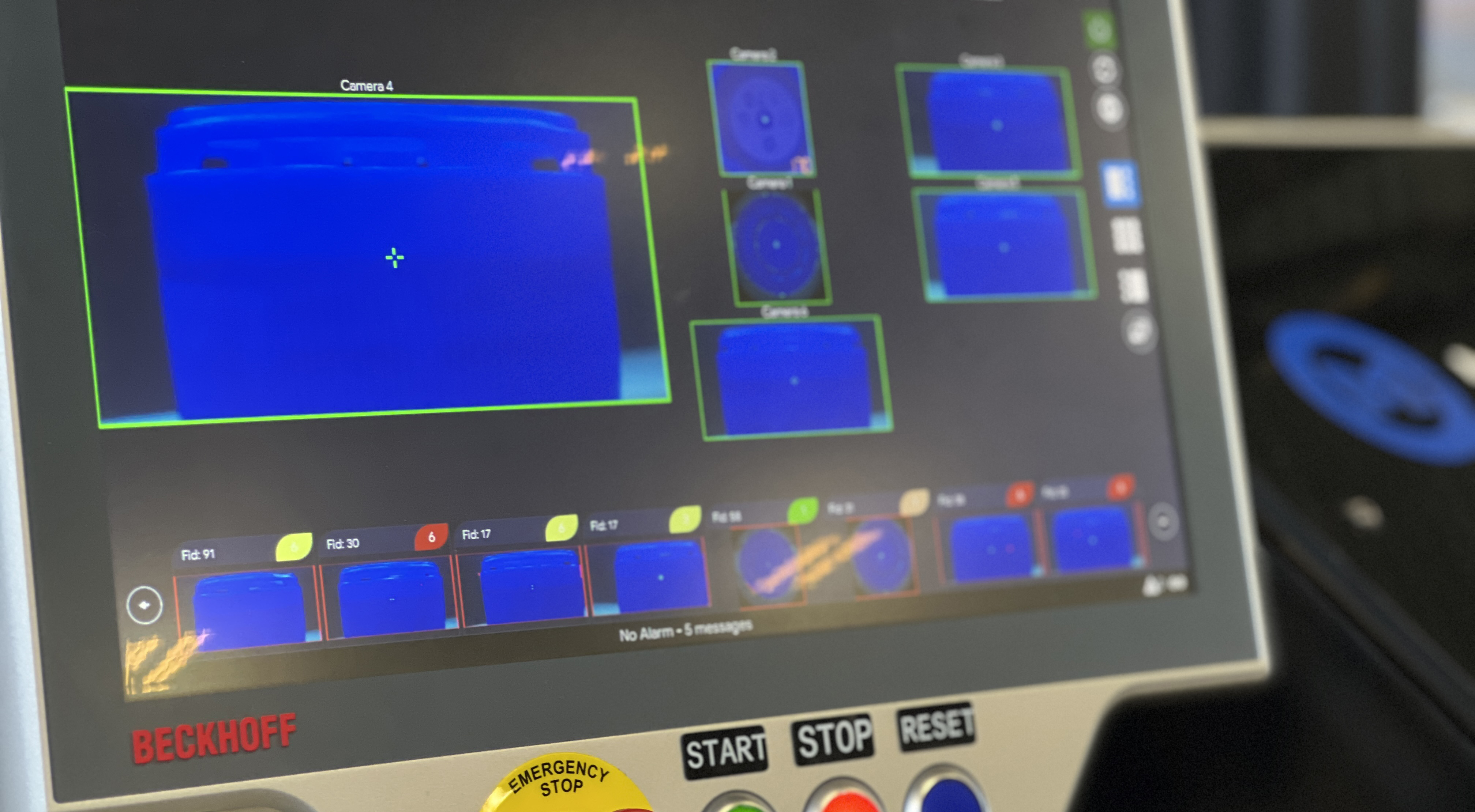

Vision & Controls

in a Single HMI

Beyond performance, the MMC QTV vision systems lead in usability with a user-friedly and customizeable interface that combines Vision and Controls in a single HMI. Quality data, recipe management, automated reporting and machine performance all easily accessible from one location.

SCHEDULE A DEMO

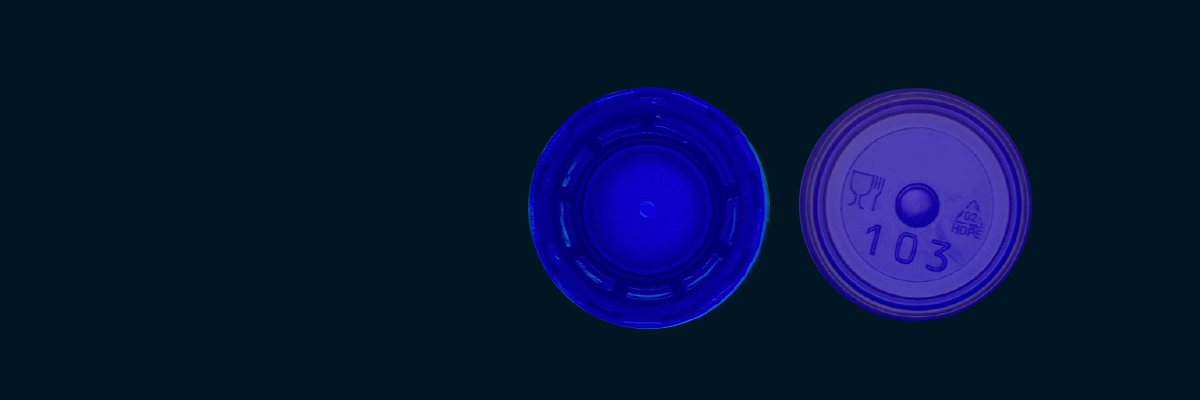

True Performance Means Flexibility

Our systems offer leading class performance across almost any size, color, geometrical shape and liner type.

Our systems are especially sought out for use with orientation assembly, embossed or engraved closures, printed liners, valve liners, donut liners, elliptical line and black & white closures.

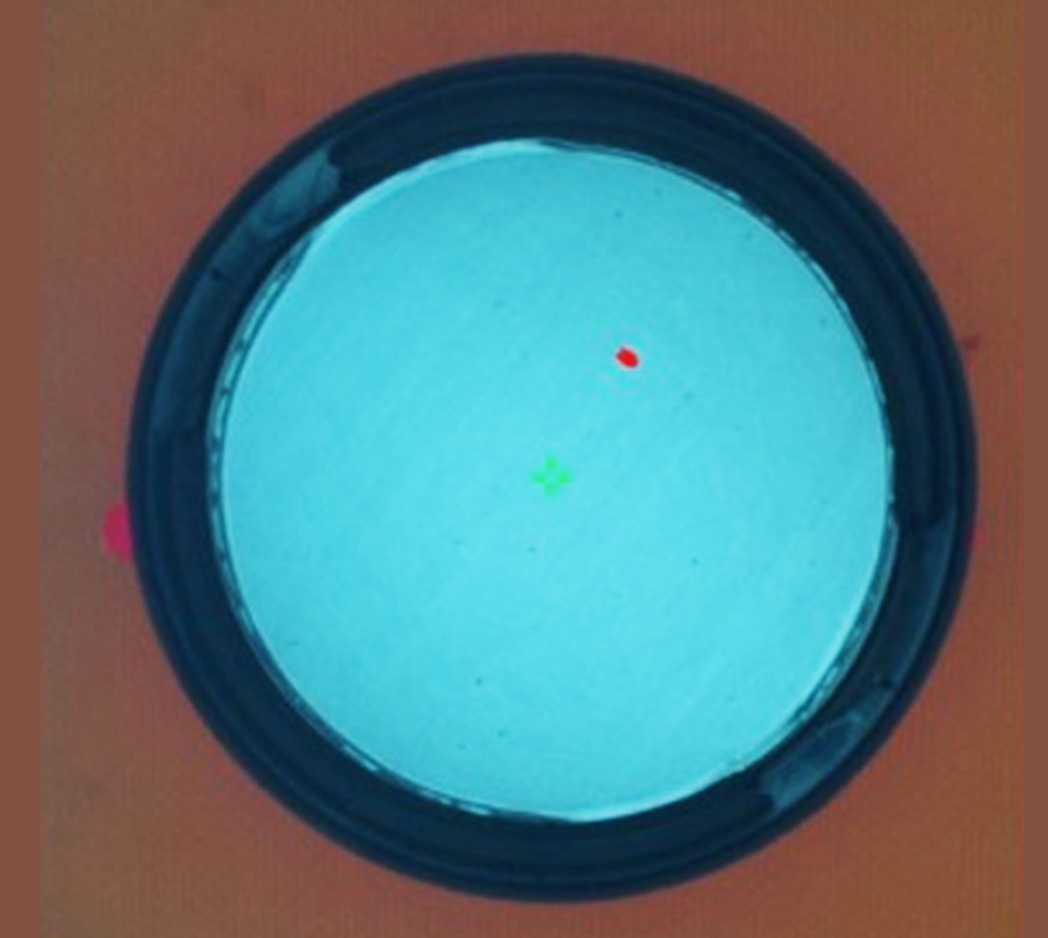

Some examples of the type of defects our systems capture:

Half-Moon/Cut Liner Error

Liner Incomplete

Upside Down Liner

Liner position incorrect

Contaminant Error

Contaminant Present on Liner

Closure Ovality Error

Geometrical Defect

Why Choose MMC Vision Systems

Performance, Focus, Speed

Our next generation systems are the perfect companion to our automation equipment line. Built for a seamless integration from lab to production, they are always the standout choice at any speed.

Dedicated

In-House Team

MMC has it's own In-House vision inspection, image processing and software development engineers.

Systems Optimized for Caps & Closures Inspection

Expertise, products, tools, features, algorithms, cap handling, etc. are all tailored to liner and closure inspection.

Seamless Integration with Controls

Our intuitive HMI simplifies operator tasks and offers a seamless integration between controls and vision in a single dashboard.

Quality at High Speed

We offer the unique capabilities to achieve 360deg vision inspection, spark inspection and precise parts tracking at up to 2400ppm.