Welcome to our special coverage of the NPE 2024 in Orlando. Today, we have with us several of our MMC team leads, responsible for the innovations we are showcasing at the NPE. Let's dive into the conversation.

So, let's talk about the journey from lab to production, your theme for the show. How does MMC support clients in transitioning their closure designs and prototypes into full-scale production?

Patrice: We all know that innovation in packaging at the design level is key. At the same time, when you combine complexity in package design with the evolution in materials, it means bringing that innovation into production with a competitive time-to-market is still a challenge for most closure manufacturers. MMC aims to change this paradigm. From the Lab Slitter, to our high-speed production slitter, vision system lab, and new software solutions, we aim to show how we can accompany customers in the product development cycle, help them achieve a seamless transition from design phase to industrialization phase, then simplify how they can improve OEE of the whole production line.

“ MMC aims to change the paradigm in post-molding automation.”

MMC has always been known for innovation in the post-molding automation space. When looking at the specific solutions you are bringing the NPE, it is clear that MMC has grown from a pure equipment builder to a technology company focused on connected factory.

Yves: Having been in the organization for over 20 years I can attest to this transformation. At the NPE we are bringing to life the three pillars in our product offering. Equipment with our High-Speed Slitter. Software with our connected factory offer. And advisory services with our Lab Slitter. I believe visitors will see a new MMC.

You are known in the US market and around the world for your Lining machines. Why showcase a high-speed slitter?

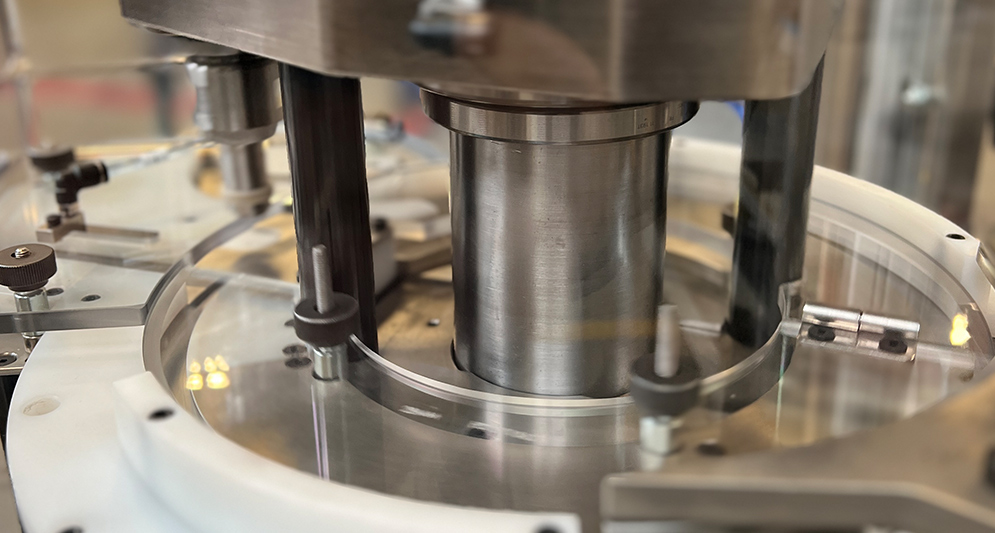

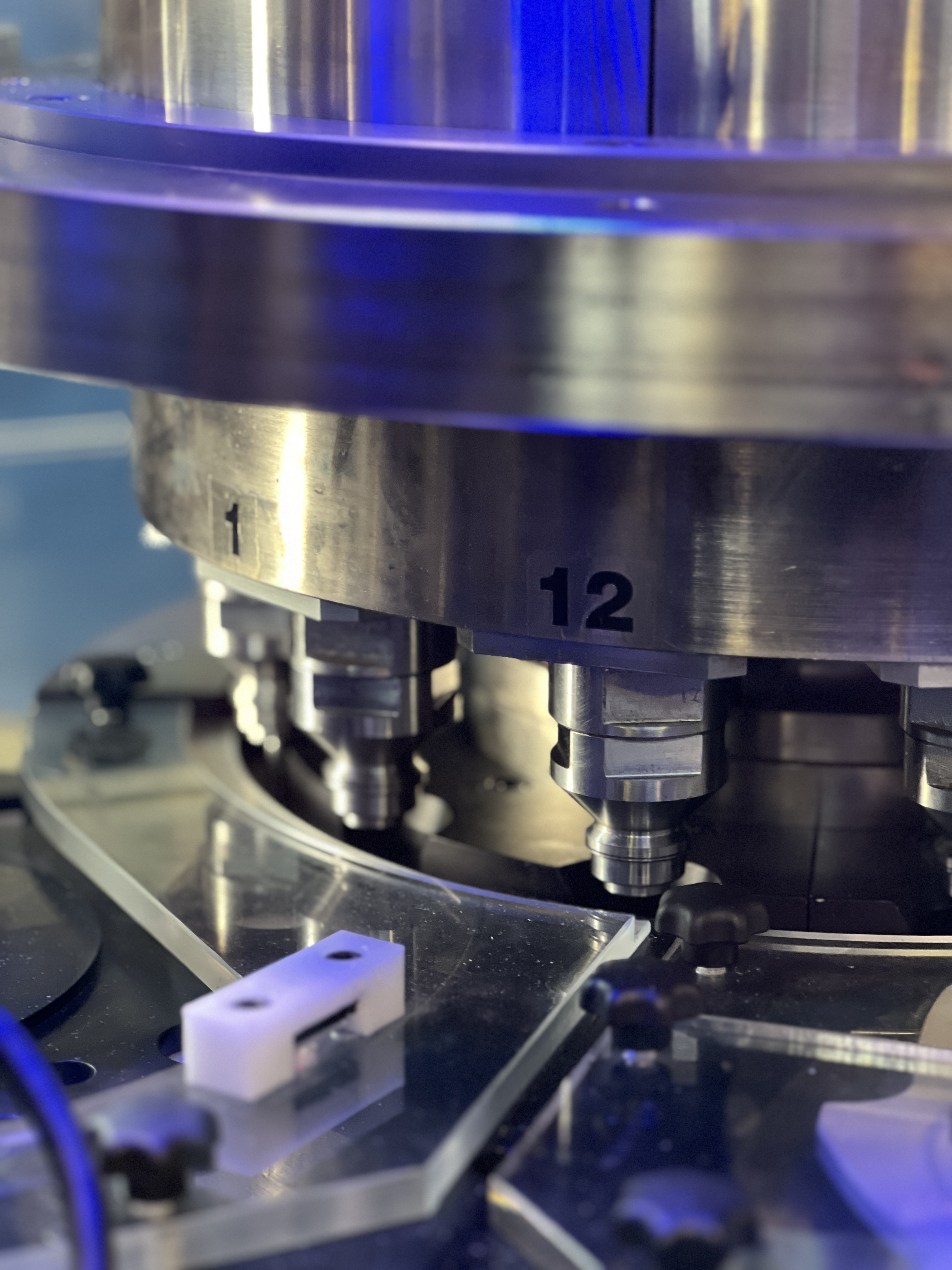

PM: Over the past several years, driven by the demand for tamper evident closures, as well as a focus on improved sustainability, we have seen a transition to liner-less solutions. Our High Speed Slitter demonstrates our leadership in this space.

“ Our aim was to build a leading class machine that would set a new standard and benchmark in the category.”

Denis: When we started the process back in 2016, our aim was to build a leading class machine that would set a new standard. We believe we achived this objetcive. The machine will be running at 1800 ppm at the NPE, but can go up to 2400 ppm in the production environment. This is an incredible 40 caps/ sec, with an unmatched performance, stability and low vibration. Every one of our technical partners and clients who have seen the machine first hand, have mentioned that this is a true world class solution.

YL: It's a standout piece of equipment and a testament to the work by all the teams at MMC. We're actually very proud of the fact that MMC has already been awarded two patents for the design, with an additional two, patent pending.

1800ppm , 40ppm/sec is extremely fast. The system is capable of 2400ppm. How did this impact your solution for vision?

YL: It certainly put the team to challenge. Similarly to the other peripherals on the machine, we redesigned our Vision system to deliver at these speeds. As the closures are linerless, deliveriing quality meant starting with bore seal vadiation using a spark test. Four aditional cameras veryfiy sides, band, contaminants

Did this also include cavity recognition?

PM: Absolutely. In fact we are the only vision system availablity that offers this level of performance at up to 2400ppm.

For visitors who want to test the performance of our systems on their closures or have a particular challenge we are setting up a vision lab where they can schedule a demo with our Technical and Vision Teams.

You mentioned that a key part of your approach to the connected factory lies in the software solutions you are working on. Can you take us though some of the innovations your will be presenting at the NPE.

PM: At the core by separating the IT and OT layers, enabled us to creat additional functionaly to our ICON controls, including new automatic reporting and recipe management.

One of the technologies we are most excited about showing is a preview of our ICONnect software; because it demonstrates the power and real life application of the connected factory. Based on our proprietary information model, and leveraging the data generate by our machines, it is an example of how we can give clients a real time view of each machine on the entire production floor, using custom dashboards.

As it's based on the OPC/UA protocol, It means easy to deploy and integrate accross client facilities.

Is ICONnect available for older machine or only new machines?

PM: Clients can purchase and configure ICONnect on all ICON 3.0 machines. Clients with older machines running ICON 2.0 can take advantage of this new functionality We can upgrade older machines running ICON 2.0

My last question is about what you are most looking for at this years’ NPE?

PM: Speaking for the whole team, beyond the solutions themselves, the exciting part is seeing the vision for the new MMC take form. We wish the entire team could be there with us.

Thank you all, and see you in Orlando. South Hall, Booth #S13123.

NPE 2024. South Hall, Booth #S13123.